Lumber Grade-Marking History: 1922

Introduction

1922 was a year that opened with tragedy. The Knickerbocker Storm hit Washington, D.C. on January 28th – still, the biggest ever recorded – and caused the Knickerbocker Theatre to collapse, unfortunately claiming the lives of 98 people. Construction on Yankee Stadium in the Bronx began in May. If you’ve ever seen the Lincoln Memorial, this was the year during which it was first dedicated. Throughout the course of the year, history would be made again and again.

This is true both in the larger sense and of course in terms of the lumber industry’s continued evolution.

In the following section, you will find out more information about essential topics like the Gulf Coast Classification – something that was itself used in conjunction with foreign specifications and, because of that, was in the process of heavy and much-needed revision. You will learn more about the necessity for uniform grades, and you will watch as people across the industry realized that the grading of lumber was every bit as much an art as it was a science. But more than anything, you will continue to see the perseverance and the passion of an entire collective of people as fascinating and innovative solutions to pressing problems were achieved, time and again.

We hope that you will find it eye-opening and that it will continue to shed light on just how far we’ve come, both as a profession and as a collective of people who are all dedicated to a singular cause.

1922

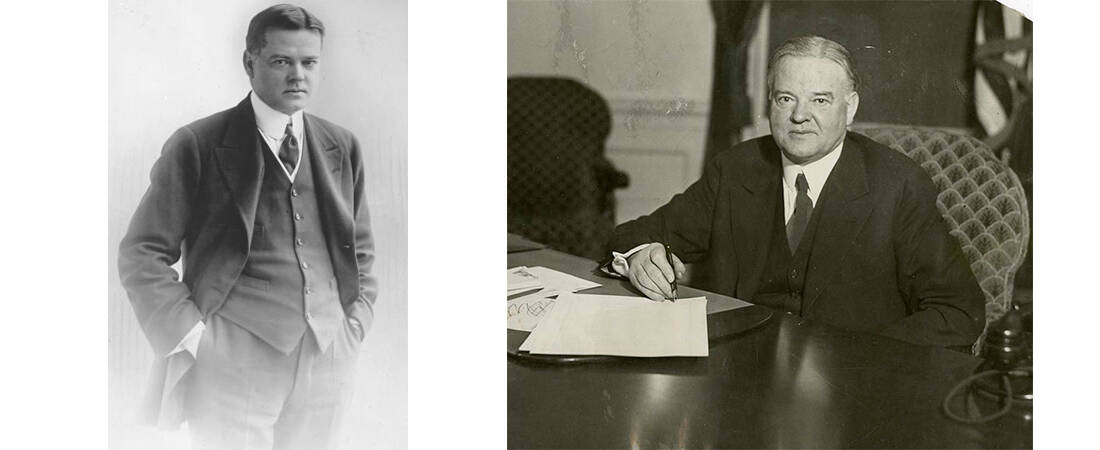

The movement for standardization of lumber, nationally, already started by the American Lumber Congress received a stimulant by the suggestion of Secretary Hoover that through cooperation with the Division of Simplified Practice, which had been created within the Department of Commerce, a great saving could be accomplished for the producers and consumers of lumber. In this connection, the plans previously inaugurated by the Southern Pine Association for the grade-marking of lumber to prevent substitution attracted interest. The National Lumber Manufacturers Association, who conducted the American Lumber Congress because all wood species were included, promoted and sponsored the cooperation with the Department of Commerce. A Central Committee on Lumber Standards was appointed – representation on which was had by the Southern Pine Association. A Consulting Committee, consisting of lumber producers, distributors and all classes of specifiers and consumers functioned, in particular with the Forest Products Laboratory, to determine permissible shrinkage and dressing loss. Air-drying and kiln-drying tests were conducted.

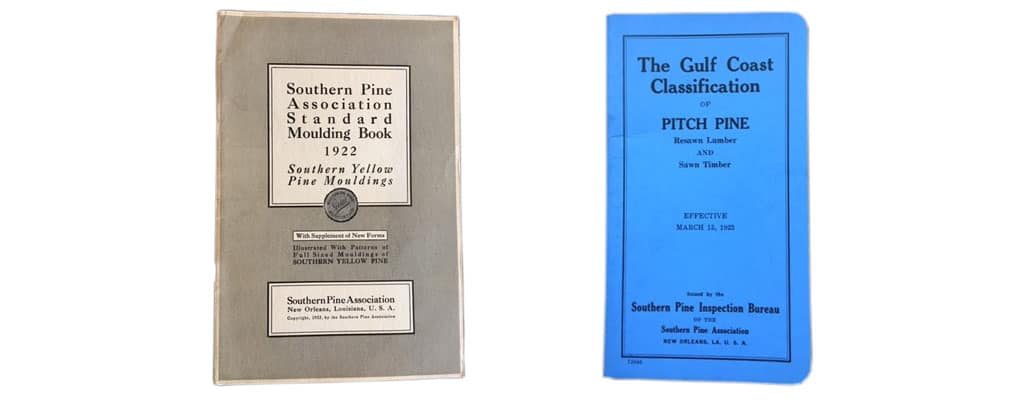

The Gulf Coast Classification used in conjunction with foreign specifications was revised. The Standard Moulding book, improving and simplifying moulding patterns through recommendations of lumber manufacturers and architects, was reissued.

A solution to the short- and odd-length problem was sought. With changing economic conditions in the lumber business and the coincident closer utilization of raw material, it was thought timely to consider that an increase in short lengths be included in orders of stock lengths; or to separate the short lengths from the longer lengths and offer them separately at different prices.

There being a variety of interpretations as to what disputing parties claimed to be trade custom, a code of ethics seemed advisable to simplify and eliminate friction in the business of buying and selling lumber. General arbitration and claim inspections required the guidance of an accepted and established a code of business practice which the manufacturers, wholesalers, and retailers would feel honor-bound to recognize.

The necessity for uniform grades, the admission that the grading of lumber was not an exact science, and recognition of the continuing practice of grade manipulation by unscrupulous dealers, was again emphasized. Non-subscriber as well as subscriber mills were being serviced as to claim inspections; 694 inspections being made for the former, and 992 for the latter, during the year. Widely advertised that the Inspection Service was available to all who desired the grade and quantity of southern pine lumber officially determined, there seemed to exist manufacturers and wholesalers who persisted in not knowing that the Association rendered this service. The beneficial effect of regular mill inspections on grade uniformity was demonstrated by the wide range above and below any specifically invoiced grade shipped by non-association mills, in comparison with the narrow range of that shipped by subscriber mills. The Inspections Department contacted many instances where lumber had been purchased and received from subscriber mills as of one grade and resold and re-invoiced as another.

Lumber branding was again considered. Suggestions for mechanical devices to grade-mark were solicited. 72% of the subscribers indicated their willingness to grade-mark when a satisfactory mechanical means became available – the 50% amount being the factor previously agreed upon as sufficient for procedure. An improved McDonough Branding Machine was exhibited.

Secretary of Commerce Hoover stated at the annual meeting of the National Lumber Manufacturers Association in Chicago, April 1922, that:

In the matter of business and labor practices of the minority I need not recite the repeated exposures in all directions that have sickened the public during the last twelve months. There are other things that have not yet been exposed. I have no taste for demagogic statements. I do not have an aspiration for constructive remedies.

Let us take a single material – lumber. Several leading manufacturers inform me that the time has come when we must have a guarantee against short deliveries and fraudulent alteration of qualities. The product of the honest mill man must reach the consumer as the manufacturer wishes his product to reach the consumer. Also, he must have protection from the crooked competitor. Is it not possible for the National Lumber Manufacturers Association to take upon itself the duty of giving a brand to lumber that will show its content and grade? Many commodities are assured as to quantity and grade under the inspection and rules of our voluntary trade associations. If you think it wiser to do so we could probably secure the enactment of a ‘pure food law’ in all building materials. I would much rather see the trades themselves establish their own standards.

Members of the National Lumber Manufacturers Association adopted the resolution at the end of the session which reads:

Hon. Herbert Hoover, Secretary of Commerce, addressing a meeting in Chicago, April 4, 1922, of members of this association and others, requested its assistance in giving protection to buyers and users of lumber, by encouraging the observance throughout the lumber trade of definite standards of grade and quantity; by promoting the adoption and recognition in practice of standard sizes and grades, the comparative lack of which creates confusion; and by discouraging the making of deliveries short in amount of the volume of lumber billed. Secretary Hoover stated that he would welcome the appointment of a committee of representative lumbermen to come to Washington to confer with him concerning these matters, and of the appointment of such a committee he was assured. Therefore be it resolved, that the President appoint such a committee to consist in number of not less than one member from each regional association, and to include also such others as may be appointed after consultation with the Secretary of Commerce; and that if the retail lumber dealers association appoint committees to hold similar conference with Secretary Hoover, the committee of the National Lumber Manufacturers Association be authorized and requested to join, as far as the Secretary of Commerce may suggest, with such other committees: That, for the guidance of the committee, the following principles be adopted:

1. The grade-marking of lumber, as a means of protecting the buyers and users of lumber.

2. Such marks, in connection with the grade-marking, as will make possible the identification, through the association, if any, to which it belongs, of the mill manufacturing and shipping the lumber.

3. The placing in each car of lumber at the mill shipping such lumber, of a card giving a piece tally of the grade or grades of the lumber contained therein.

4. A simplification and standardization of sizes, fair and equitable to the producers of lumber, which will eliminate the waste incident to excess variety, and confusion of sizes.

5. The rigid maintenance of grades (and of standard sizes if established) through association inspection.

That this association expresses to Secretary Hoover its appreciation of the opportunity accorded by him to representative lumbermen through their respective associations, to formulate standards and adopt means for promoting at all times and in all places the honest and efficient conduct of the lumber business and the suppression, wherever they exist to the detriment of the lumber industry and to the injury of the public, of inefficient, wasteful, or dishonest practices.

The following principles of procedure were recommended and adopted at the Fourth American Lumber Congress, in Chicago, April 7, 1922:

(a) The grade-marking of lumber, as a means of protecting lumber Buyers.

(b) Marks, in connection with the grade-marking, by which the mill manufacturing and shipping the lumber can be identified through the association to which it belongs.

(c) The placing in each car of lumber at the mill shipping such lumber of a card giving a piece tally of the grade or grades of the lumber contained in such car.

(d) The rigid maintenance of grades through association inspection.

We believe and desire to commit the entire lumber trade in practice to a policy of fair dealing, honest grades and the proper and complete fulfillment of obligations and contracts.