If you had to pick a single word to describe everything that was happening in 1924, “innovation” would certainly come to mind pretty immediately.

Continue reading

Lumber Grade-Marking History: 1923

1923 was many things, but it was also among the most important in the entire industry of the Southern Pine Association – as this was the year that grade-marking machines were finally perfected. This, in turn, gave way to the successful development of a comprehensive, holistic plan to establish the practice of grade-marking lumber across the country.

Continue reading

Lumber Grade-Marking History: 1922

1922 was a year that opened with tragedy. The Knickerbocker Storm hit Washington, D.C. on January 28th – still, the biggest ever recorded – and caused the Knickerbocker Theatre to collapse, unfortunately claiming the lives of 98 people.

Continue reading

Lumber Grade-Marking History: 1921

1921 was yet another year during which the world would change forever – however, it was less the product of any one major event and more about a series of smaller ones, taking place “behind the scenes” on the world stage.

Continue reading

Lumber Grade-Marking History: 1920

For determining lumber grades in dispute, the Inspection Department, which applied grading rules and standard specifications, performed valuable and indispensable service. Of 1,448 claim inspections, 628 were made at the request of non-members of the Association, who paid the per diem fee and all expenses for the inspection service.

Continue reading

Lumber Grade-Marking History: 1919

1919 was another year that left an incredible mark on the globe, and particularly on the United States. In July, the United States Army sent a convoy across the continental U.S. to see whether or not it would be possible to cross all of North America by road. This particular effort took many months to complete and was woefully inefficient, but because of it, the U.S. Highway System would be born.

Continue reading

Lumber Grade-Marking History: 1918

Even though we don’t necessarily think about these early years of the 20th century as critical to human history today, all it takes is one cursory glance at some of the things that happened during 1918 to see that if anything, that may just be a bit of an understatement.

Continue reading

Lumber Grade-Marking History: 1917

1917 was a year of many firsts. Jeannette Rankin officially became the first female member of the United States House of Representatives in March of that year, right around the time that Woodrow Wilson was sworn in for his second term as president. The Republic of China would later terminate all diplomatic relations with Germany, something that would act as the starting point for a lot of the conflict born in the coming decades.

Continue reading

Lumber Grade-Marking History: 1916

1916 was a year that gave us a great many things for the first time, many of which our lives literally depend on today. On New Year’s Day, the British Royal Army Medical Corps carried out not only the first successful blood transfusion in history, but they did so using blood that had already been stored and cooled.

Continue reading

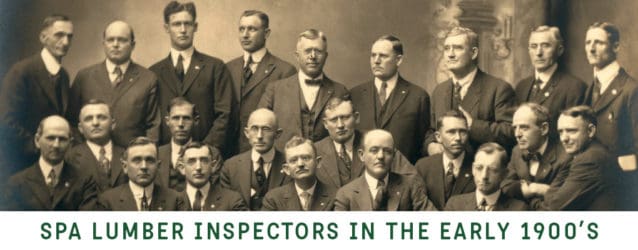

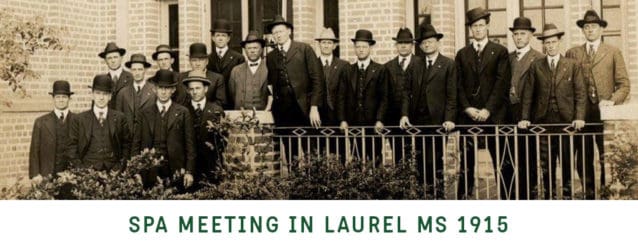

Lumber Grade-Marking History: 1915

About the History of Lumber Grade Marking SPIB has been in the process of archiving some of its historical documents. In that process, we discovered a rare and treasured story about the history of grade marking southern pine. It begins in 1883 and leads us up to 1940 when SPIB was created. W.D. Durland prepared […]

Continue reading